Polysilicon

The productions of most PV modules start with manufacturing ultra-pure raw polysilicon, which is essentially the same material used to manufacture integrated circuits (ICs) such as computer or memory chips. It is done through several melting and washing steps of quartz sand.

Wafer

The liquid silicon is cast in blocks, which is also known as ingots. These ingots are then cut into thin discs, or wafers.

There four major commercial wafer manufacturing techniques:

Mono-crystalline Wafers

Multi-crystalline Cells

Polycrystalline String Ribbon

Amorphous Cells

Cell

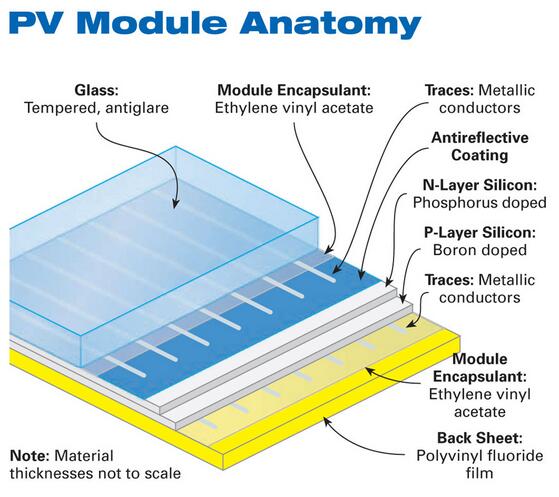

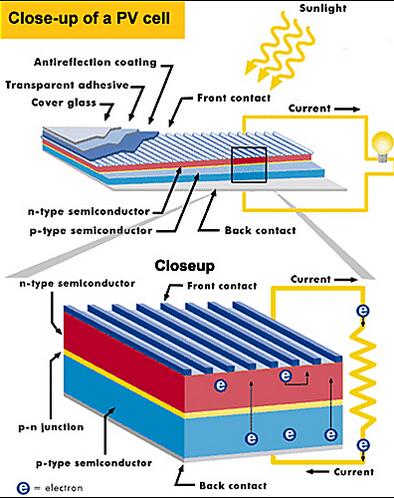

A PV cell consists of two thin layers of semi-conducting silicon. Each layer is "doped," or infused with a small amount of

another material that prevents all the electrons from being locked in the pure silicon lattice structure.One layer is doped

(usually with phosphorus) so that it has slightly too many electrons, and the other layer is doped(usually with boron) so that it has slightly too few electrons. This difference produces a small electric field between the two layers,which gives the electrons a direction to flow when they get knocked out of place by a photon (packet of light energy).TLNZ Solar buys mono-crystalline wafers and multi-crystalline cells and processes them into solar cells.There are two major steps in making cells from wafers:

Doping – create a built-in electric field via gas diffusion, heat diffusion, or spray diffusion of phosphorus.Anti-reflective coating–apply a layer of silicon nitride (SiN) which offers both anti-reflective properties and surface passivation.This passivation acts act as recombination centers in the material by saturating the dangling bonds.

Metallization – A grid-like metal contact made up of "fingers" is screen-printed onto front surface.